CNC turning is a particular form of precision machining in which a cutter removes material by making contact with the spinning workpiece. The movement of the machinery is controlled by computer instructions, allowing for extreme precision and repeatability.

Turning is different to CNC milling, in which the cutting tool rotates and is directed from multiple angles at the workpiece, which is usually stationary. Because CNC turning involves rotating the workpiece in a chuck, it is generally used to create round or tubular shapes, achieving far more accurate rounded surfaces than would be possible with CNC milling or other processes.

The tooling that is used with a CNC lathe machine is mounted to a turret. This component is programmed to make certain movements and remove material from raw materials until the desired 3D model is formed.

Like CNC milling, CNC turning can be used for the rapid manufacture of either prototypes or end-use parts..

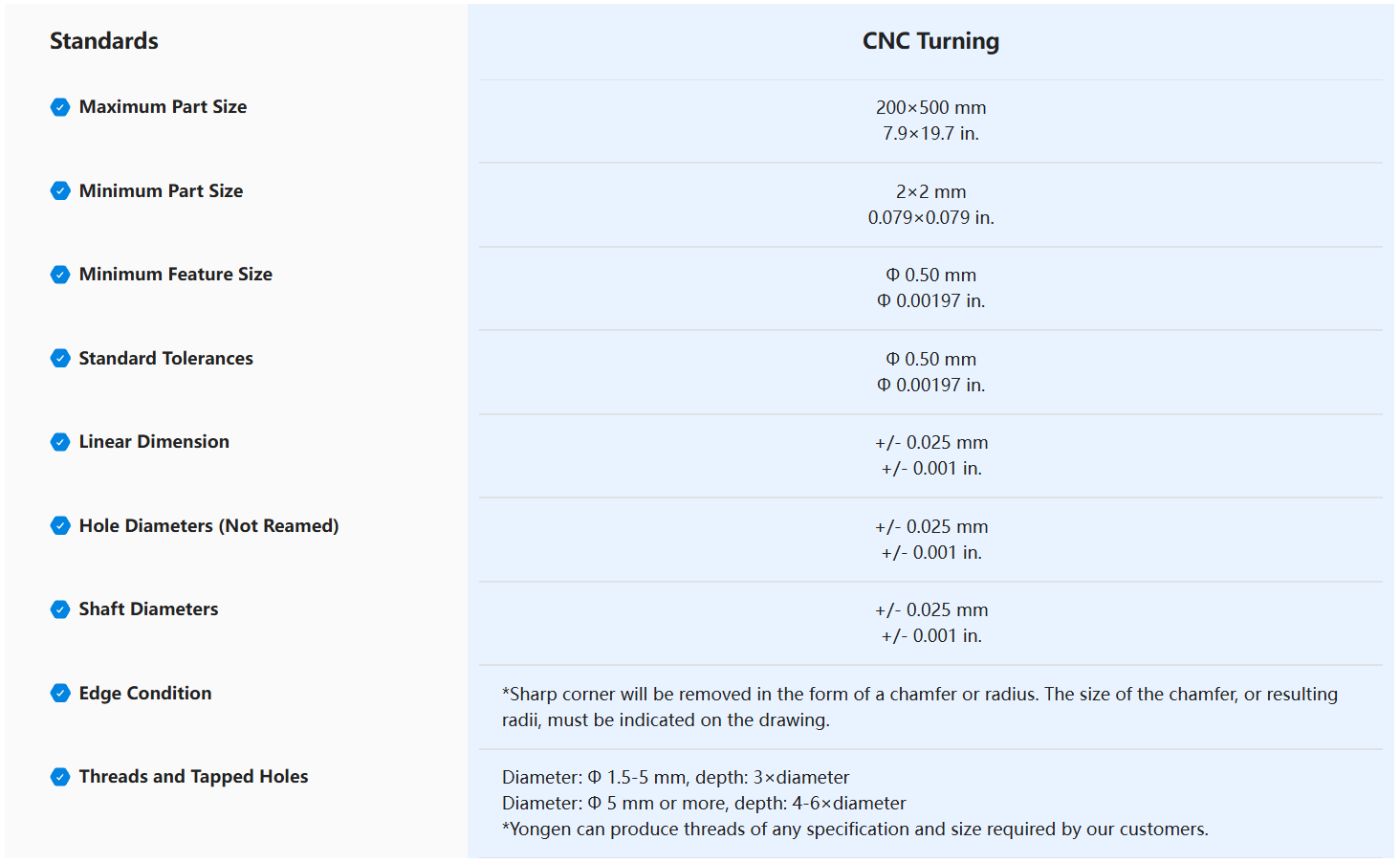

We manufacture cost-effective parts with standard tolerances and also specialize in high-precision components for advanced products, ensuring each part meets your exact specifications.

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis