Plastic prototype model is a relatively traditional processing technology, which is required in the research and development process of automotive model development, home appliance design, medical equipment, communication, security, mobile phones and other products. This type of prototype model initially requires 1 to 2 sets of engineers to compare the appearance and engineering structure of the product. After further improving the product design drawings and optimizing the structure, secondary prototype sampling is carried out to confirm that the prototype model achieves the pre production effect of the product. Data is frozen and the production of silicone molds or rapid aluminum molds, soft steel molds, and test molds begins. Plastic prototype is an indispensable product development and production process in various industries such as automotive, home appliances, medical, communication, security, energy storage, and photovoltaics.

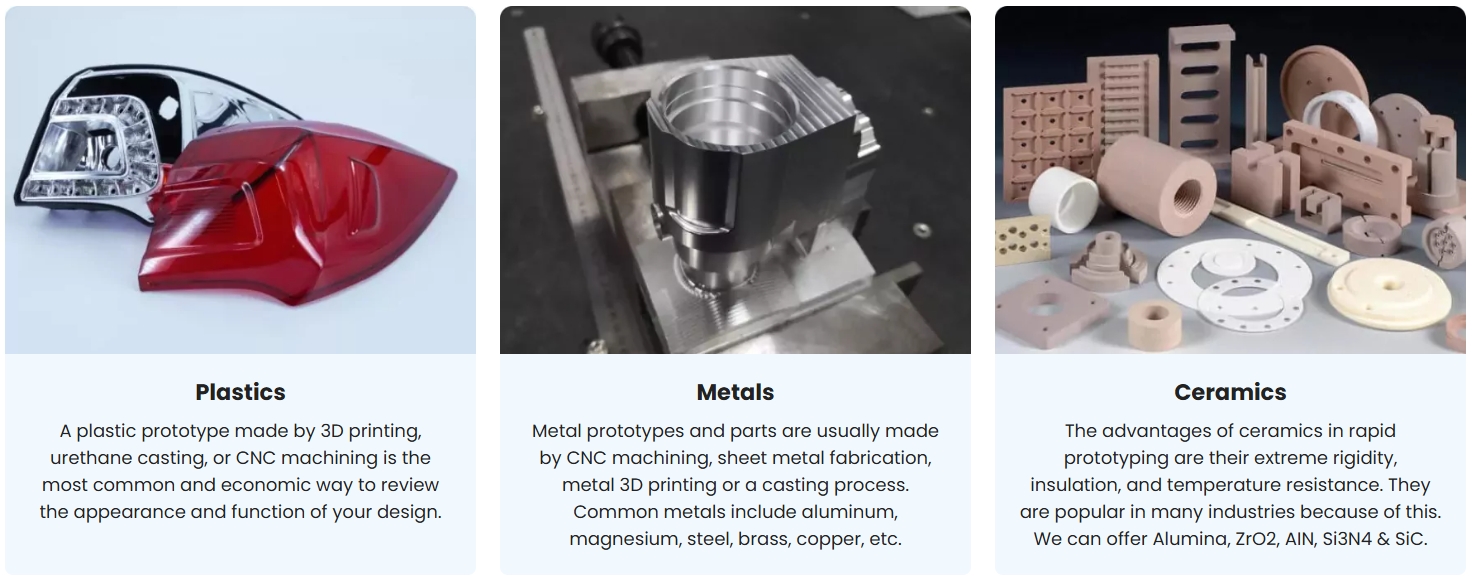

When outsourcing your rapid prototypes, it is important to find a reliable rapid prototyping company that can handle range of materials, in order to keep the whole rapid prototyping project in one place. Yongen is an ideal option in this regard. We can fabricate your prototype parts in plastics, metals and ceramics.

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis