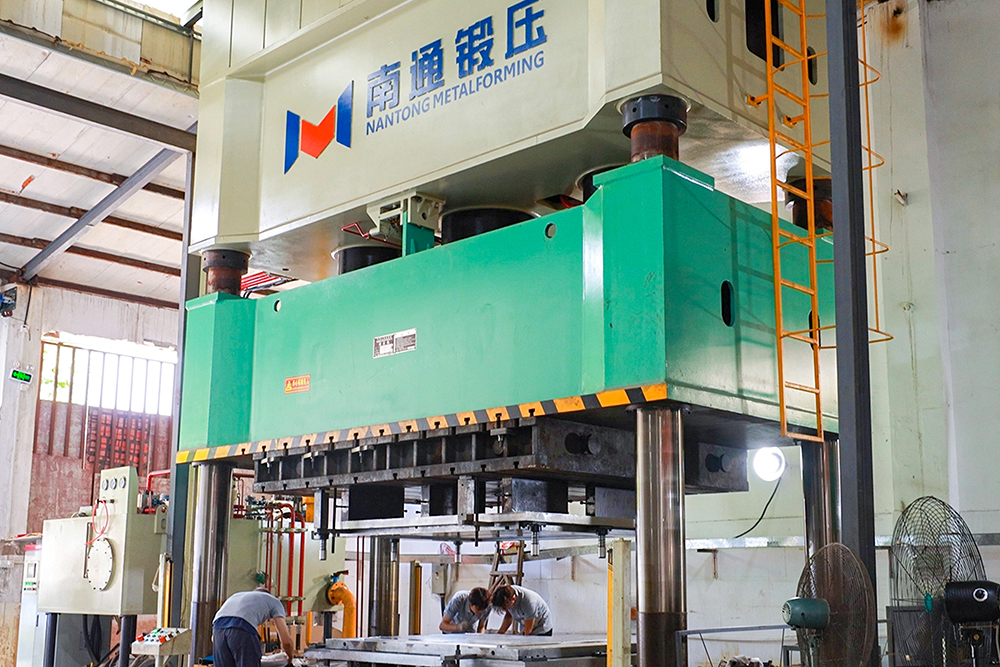

Stamping molds are generally divided into four categories: cutting molds, forming molds, flanging molds, and edge wrapping molds. Large stamping molds are commonly used in casting technology, which involves casting the body and then performing CNC machining, electric shock, precision grinding, and other processing steps to form the stamping mold. Stamping molds are generally divided into upper and lower molds, and different sizes of stamping sheet metal parts are stamped and formed using stamping equipment of different tonnages.

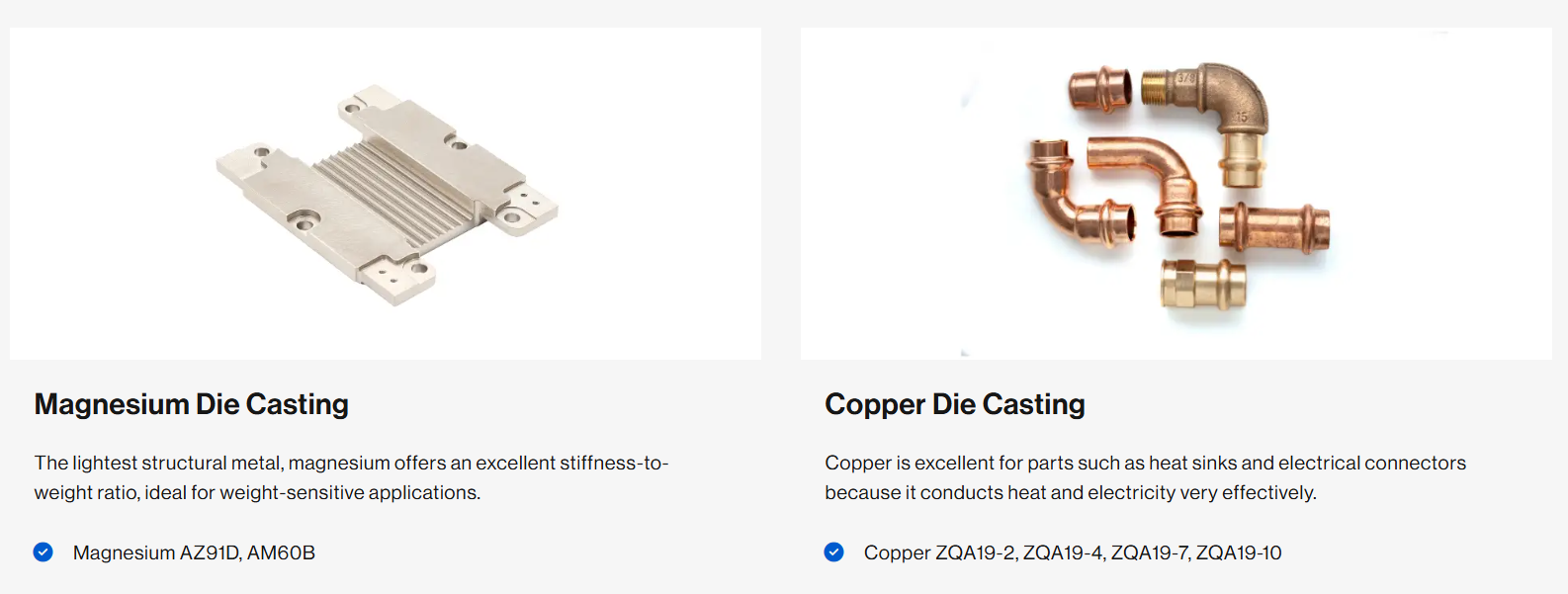

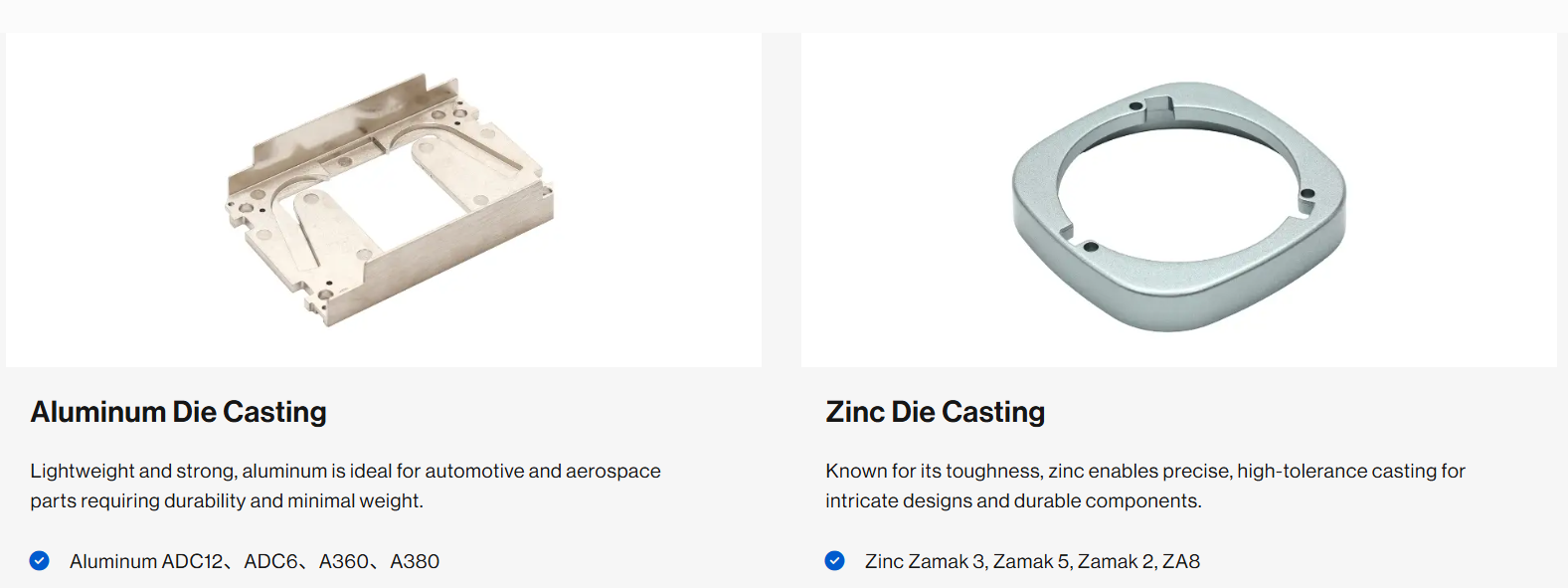

Our primary materials include aluminum, zinc, magnesium, and copper, each chosen for their unique properties and benefits in die casting applications.

Yongen provides a clear overview of our capabilities, highlighting essential performance and quality metrics in our detailed tables.

| Type | Description |

|---|---|

| Minimum Part Weight | 0.017 kg |

| Maximum Part Weight | 12 kg |

| Minimum Part Size | ∅17 mm × 4 mm |

| Maximum Part Size | 300 mm × 650 mm |

| Minimum Wall Thickness | 0.8 mm |

| Maximum Wall Thickness | 12.7 mm |

| Quality Control | ISO 9001 Certified |

| Minimum Possible Batch | 1000 pcs |

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis