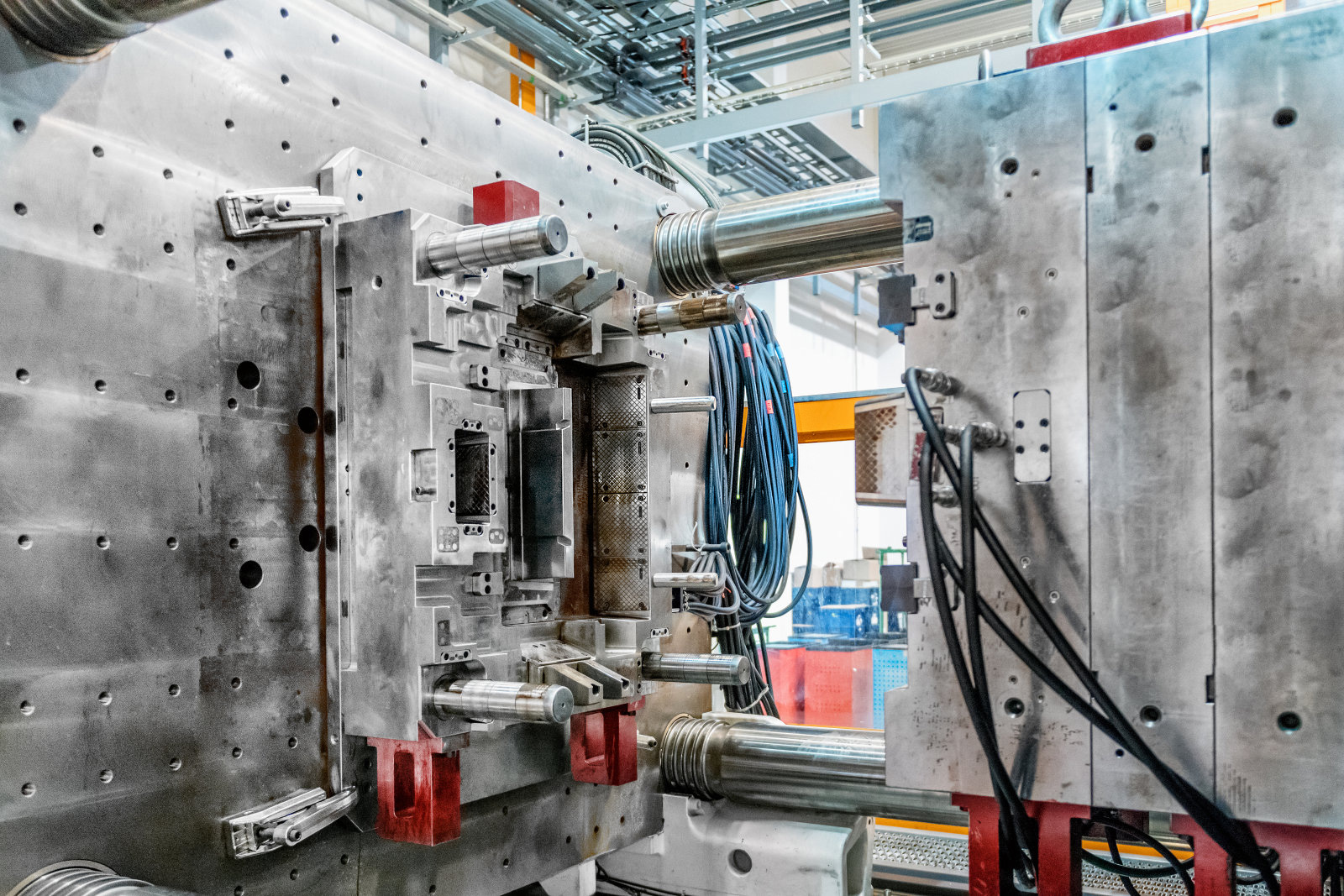

Plastic Molding are a conventional traditional manufacturing and processing method. High output and strong durability of molds, the injection molding output of officially mass-produced molds is usually over 300000 times in conventional production. If the product demand is large, several sets of replication molds will be opened. If the size of the product mold is small, the molding method of the first mock examination will be used. For example, four products will be produced by the first mock examination, eight products will be produced by the first mock examination, and then the replication mold will be opened to improve the production efficiency of the mold.

Yongen offers all types of injection molds according to your requirements, from prototype molds to production and export molds, ensuring you a reliable and high-quality service.

Classification | Advantage |

Injection Molding Prototypes | High-quality prototype molds could help you easily receive design feedback and validation. NOBLE can quickly create these molds in a matter of days, allowing you to produce small batches of plastic molded parts for functional testing and market validation. |

Production Tooling | For the production of plastic parts in large quantities, we produce high-quality production molds. Our industrial tooling is capable of creating millions of parts thanks to the use of strong, long-lasting tool steel. Depending on your particular needs, we can change the materials and building techniques. |

Classification | Advantage |

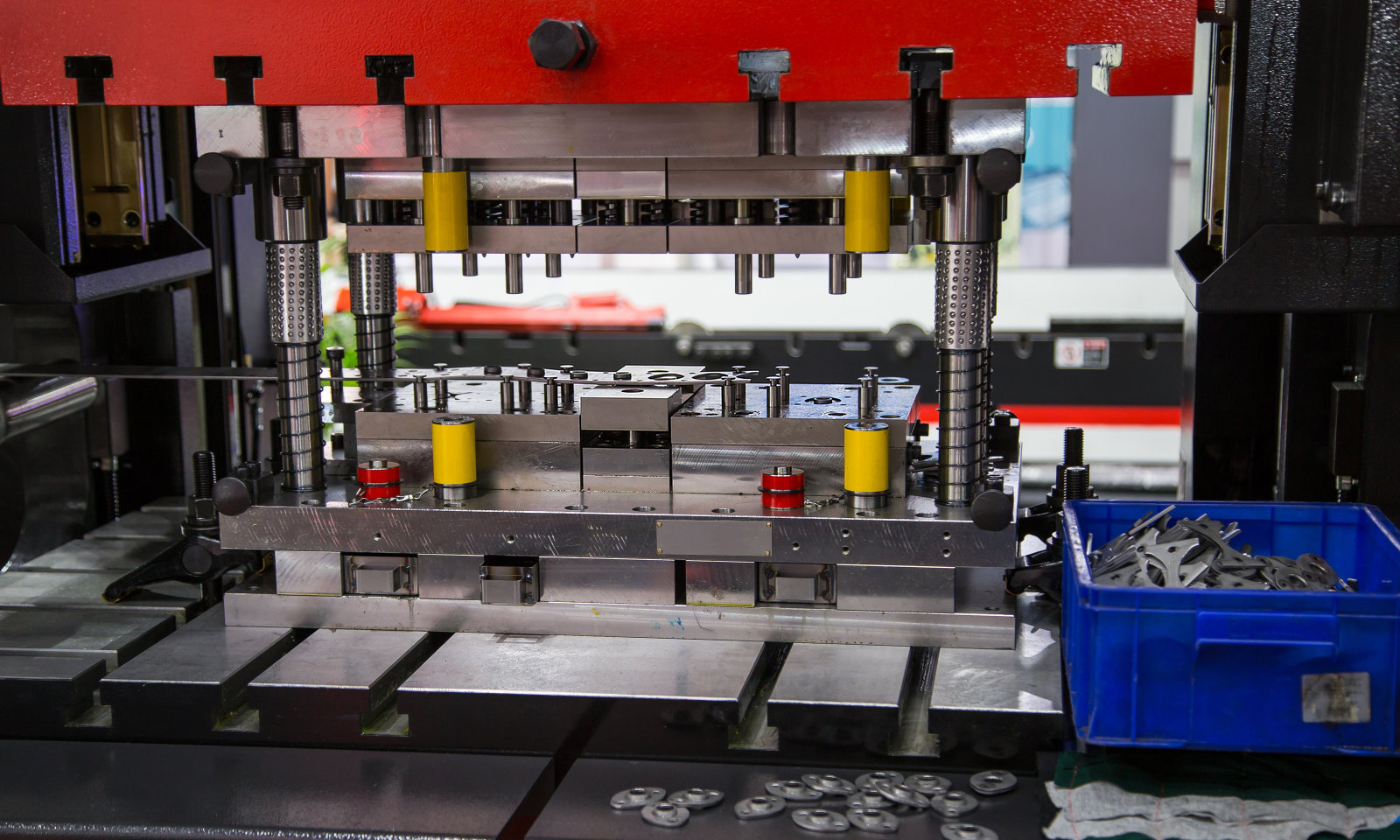

Single Cavity Mold | With premium single-cavity injection molds, you can produce plastic parts in low volumes effectively. These affordable choices for mold tooling allow you more control over the production of plastic. |

Multi Cavity Mold | Using high-quality multi-cavity molds, produce numerous plastic molded parts quickly. Our multi-cavity injection molds guarantee more efficient cycle times while providing lower unit part costs. Higher productivity enables you to produce large numbers of parts per cycle. |

Stack Mold | Incorporating innovative laminated molds could enhance your injection molding process and reduce overall part costs. NOBLE increases your molding efficiency and throughput and even creates multi-component assemblies in a single pass. Choose from molds with the same or different numbers of cavities per parting face to best suit your needs |

2K Injection Mold | A cost-effective approach for custom injection molding that uses two different plastic materials. For a product to seamlessly combine soft and hard plastics, we provide 2K injection mold tooling. Costs can be reduced by making products to order and integrating many assembly procedures into a single molding process. |

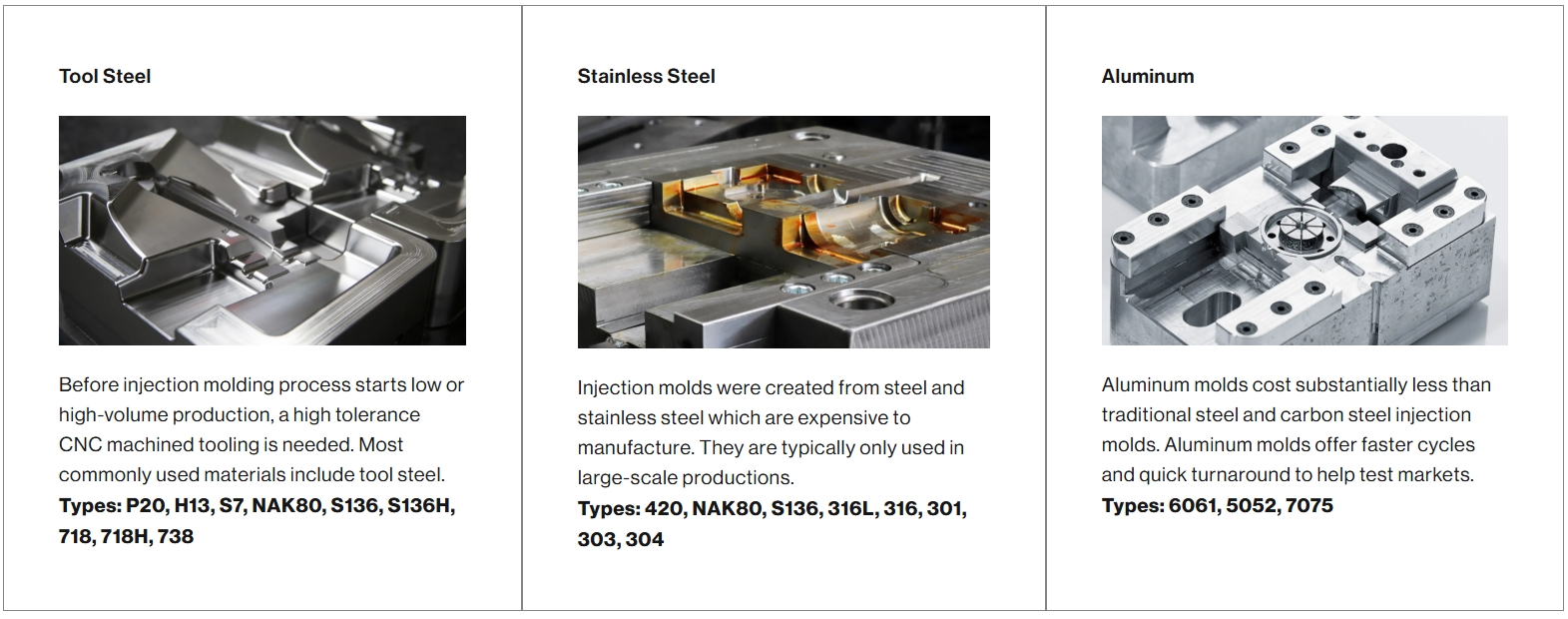

The choice of mold material largely determines its life and the quality of the injection molded part. NOBLE provides a diverse selection of material grades that cater to various stages of your product development. Our team also offers expert guidance on mold material selection to ensure optimal dimensional accuracy and aesthetic quality.

At Yongen, we specialize in crafting custom injection molds with the utmost precision and top-notch materials. You can count on us for competitive pricing and timely delivery, regardless of whether you need tooling for small production runs or for larger-scale manufacturing. Our molds meet the highest international standards and are built to last, ensuring reliability and durability for all your projects.

Mold Class | Purpose | Shot Life | Tolerance | Lead Time |

Class 105 | Prototype Testing | Under 500 cycles | ± 0. 02mm | 7-10 days |

Class 104 | Low-volume Production | Under 100. 000 cycles | ± 0. 02mm | 10-15 days |

Class 103 | Low-volume Production | Under 500. 000 cycles | ± 0. 02mm | 10-15 days |

Class 102 | Medium-volume Production | Medium to high production | ± 0. 02mm | 10-15 days |

Class 101 | High-volume Production | Over 1, 000, 000 cycles | ± 0. 02mm | 10-18 days |

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis