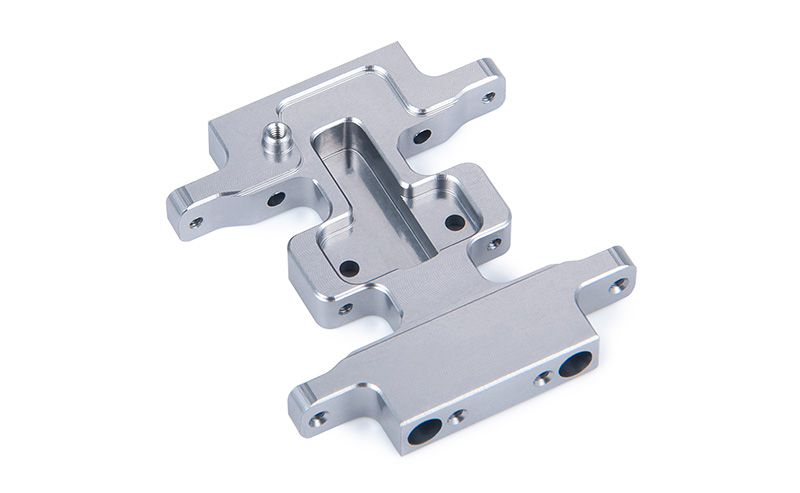

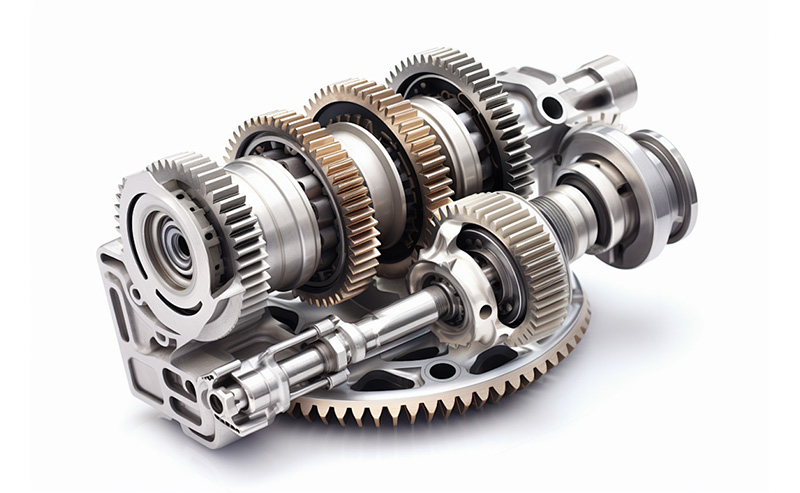

Yongen rapid prototype manufacturing services are applicable throughout the industrial equipment industry. Visualizing how a given prototype is likely to perform in the real application environment is a critical phase during any product design process. We subject our prototypes to stress and strain tests, and this ensures that we can eliminate any factor that might introduce failure in the systems we develop.

For the years we have gathered relevant experience that enables us to handle any industrial projects. Here's the gallery of industrial machinery prototypes and production parts for our worldwide clients.

We will contact you as soon as possible and reply

Leverage the same speed, precision, and reliability in machining that you’re accustomed to at Protolabs but unlock advanced machining capabilities like tighter tolerances and volume pricing through our manufacturing network.

CNC milling, turning and precision machining. We can make prototypes and end-use parts with precise and complex designs.

SLA, HP MJF, SLS, SLM technologies for functional prototyping and low-volume production. We manufacture 3d printed parts at competitive price.

Plastic injection molding, rapid and production tooling, overmolding, and insert molding. No MOQ required, all while maintaining consistent quality.

2000 ton equipment is used for stamping large automotive parts, stamping processing of new energy battery packs, and small-scale trial production and sampling

Plastic prototype model is a relatively traditional processing technology, which is required in the research and development process of automotive model development, home appliance design, medical equipment, communication, security, mobile phones and other products