Metal 3D additive manufacturing technology is fundamentally different from traditional subtractive manufacturing (such as machining). It is based on the principle of discrete stacking, where metal powders or wires are layered according to three-dimensional model data, ultimately constructing complete solid metal parts. This entire process does not require complex molds; instead, it allows for the rapid manufacture of complex-shaped metal components simply by inputting digital models, significantly breaking through the limitations of traditional manufacturing processes.

Metal 3D printing can easily produce intricate internal geometries, porous structures, and lattice designs that are challenging for traditional processes. For example, in the aerospace sector, fuel nozzles for engines can be designed with more efficient internal flow channel structures, enhancing fuel atomization and improving engine performance.

There’s no need to wait for mold fabrication; the time from design to prototype and then to final production is greatly reduced. In the new product development phase, designers can quickly validate their ideas, accelerating product iteration.

Designs can be flexibly adjusted according to customer needs, enabling the manufacture of personalized products. In the medical field, customized metal implants can be created based on a patient’s bone CT data, ensuring better compatibility and recovery outcomes.

The layer-by-layer stacking process generates almost no waste, allowing for a significant increase in material utilization compared to traditional machining methods, effectively reducing production costs and resource waste.

| SLM | EBM | SLS | |

|---|---|---|---|

| Full Name | Selective Laser Melting | Electron Beam Melting | Selective Laser Sintering |

| Types | This technique uses a high-energy laser beam to selectively melt layers of metal powder, building parts layer by layer. SLM achieves high printing precision and surface quality and is suitable for various metals like titanium alloys, aluminum alloys, and stainless steel. It is commonly used for high-precision components in aerospace and medical fields. | EBM utilizes an electron beam as a heat source to melt metal powder in a high vacuum environment. The high energy density of the electron beam allows for fast processing speeds, making it suitable for manufacturing difficult-to-melt metal parts such as titanium and nickel-based alloys, especially in large metal structures for aerospace applications. | This additive manufacturing technology is based on powder bed fusion, where a high-energy laser beam sinters powder materials layer by layer to achieve three-dimensional forming. The process involves importing a 3D model into slicing software to convert it into layered two-dimensional data. The machine evenly spreads a layer of powder (usually 50-150μm thick) using a roller. The laser beam selectively scans the powder layer according to the sliced contour information, melting or binding the powder particles to form a layer of the part's cross-section. Unfused powder remains in the chamber as support, and the chamber lowers by one layer thickness, repeating the powder spreading and scanning process until the part is fully formed. This technology does not require support structures, and unfused powder can be reused, achieving a material utilization rate of over 95%. |

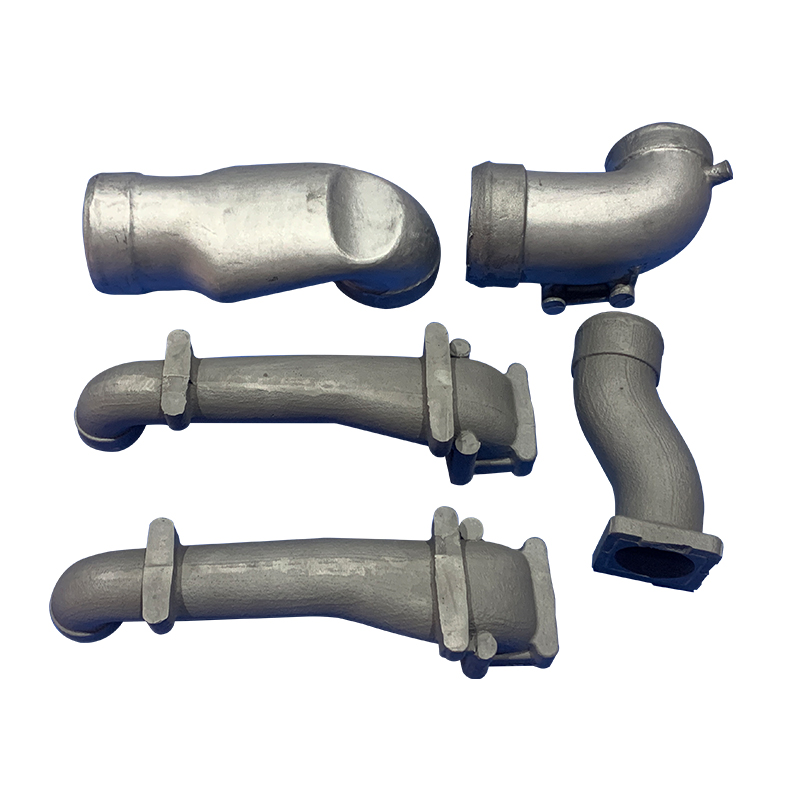

| Products |  |  |  |

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis

Data analysis