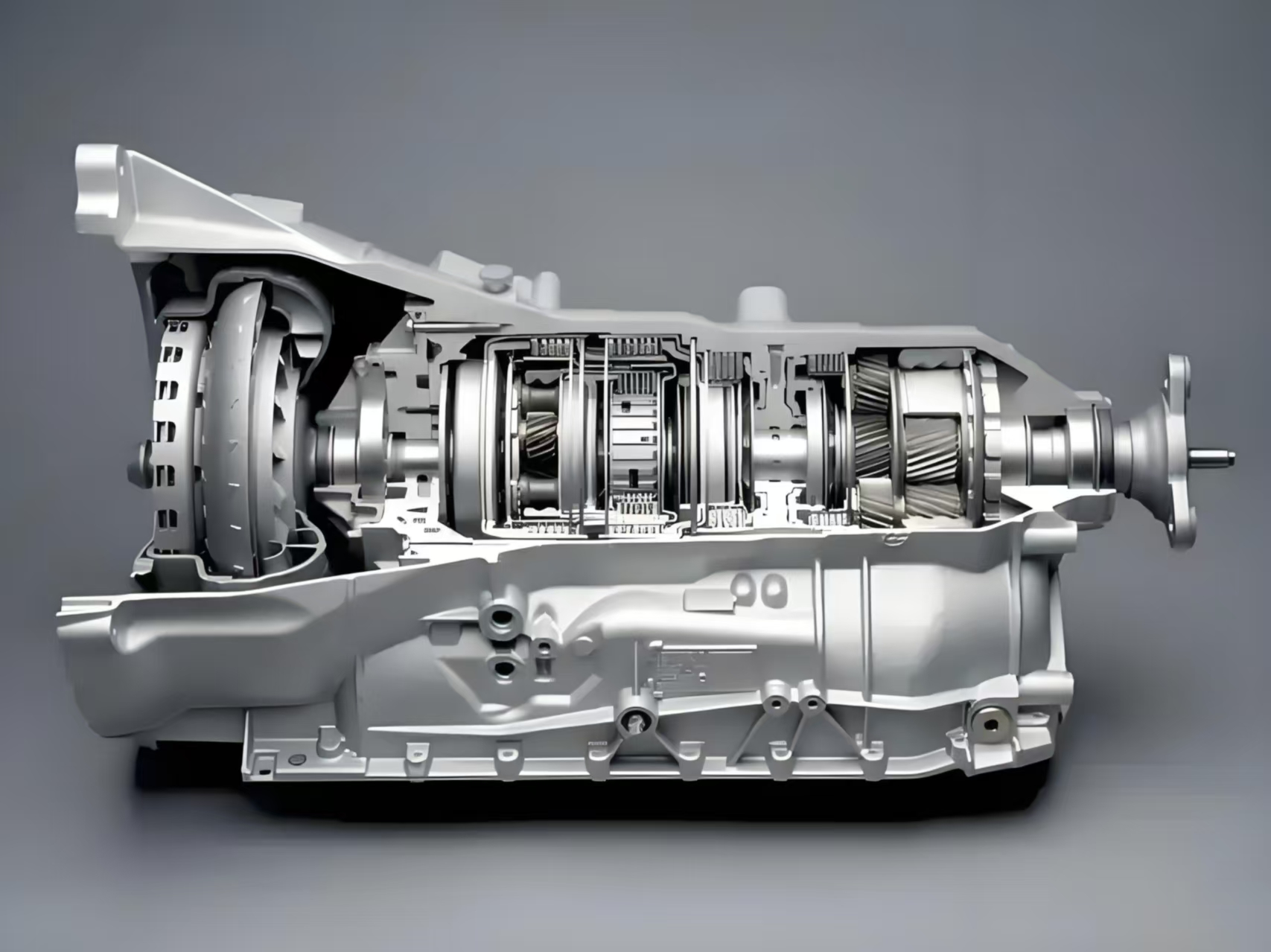

The powertrain is the soul of an automobile, and the transmission is the conductor of that soul. When the engine unleashes its powerful horsepower, the ability to transmit this power accurately, smoothly, and efficiently to the wheels depends entirely on a set of components that are seemingly simple yet incredibly complex: the gears.

The precision of the gears directly dictates the smoothness, efficiency, and noise level of power transmission. Modern transmissions demand extremely high standards for gear tooth profile accuracy, surface finish, and durability.

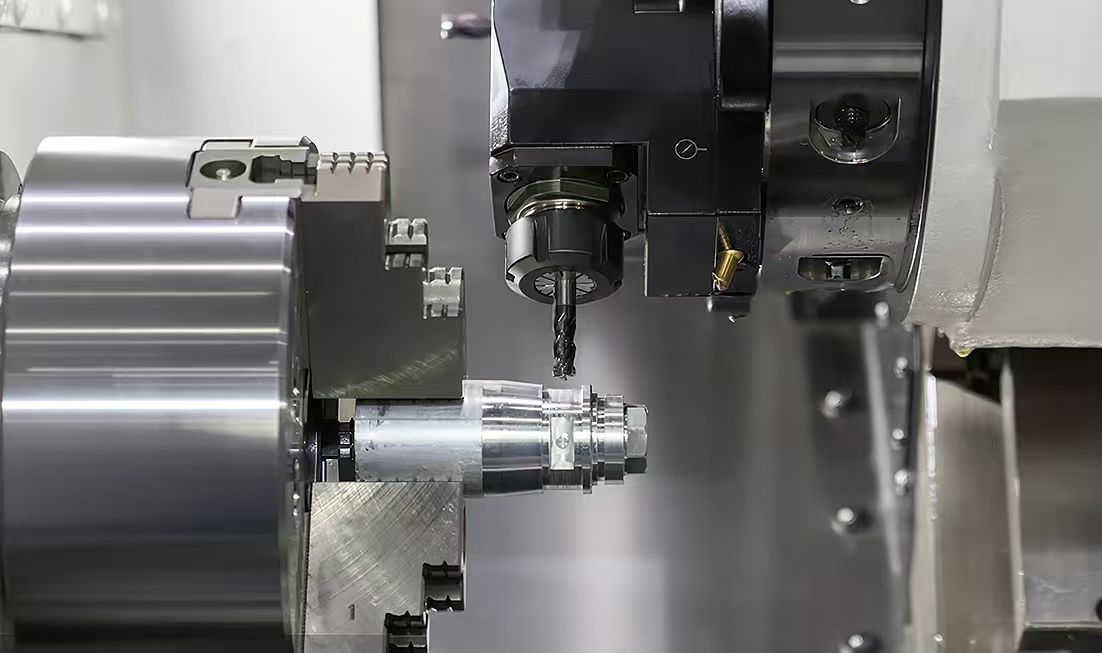

5-axis CNC technology is the crucial element for achieving this goal. It enables the precise machining of complex tooth profiles in a single operation, guaranteeing flawless geometric consistency for every gear tooth. For intricate components like dog teeth (for synchronizers) and non-circular gears, five-axis machining performs multi-sided processing with a single clamping, ensuring superior assembly accuracy right from the manufacturing source.

As a large-scale precision manufacturing service provider, we possess multiple advanced five-axis CNC machines and comprehensive process solutions, offering global clients transmission gear manufacturing services from sample prototyping to mass production. We adhere to stringent quality standards, ensuring every single gear meets the requirements for high-performance power transfer.

If you are seeking a reliable and efficient gear manufacturing partner, we are ready to provide our support.