For those familiar with 3D printing, resin materials are no stranger. Resin (photopolymer) cures layer by layer under UV light, offering distinct advantages in precision, surface quality, and detail rendition. Its material properties—such as toughness, heat resistance, or transparency—can also be adjusted according to specific needs.

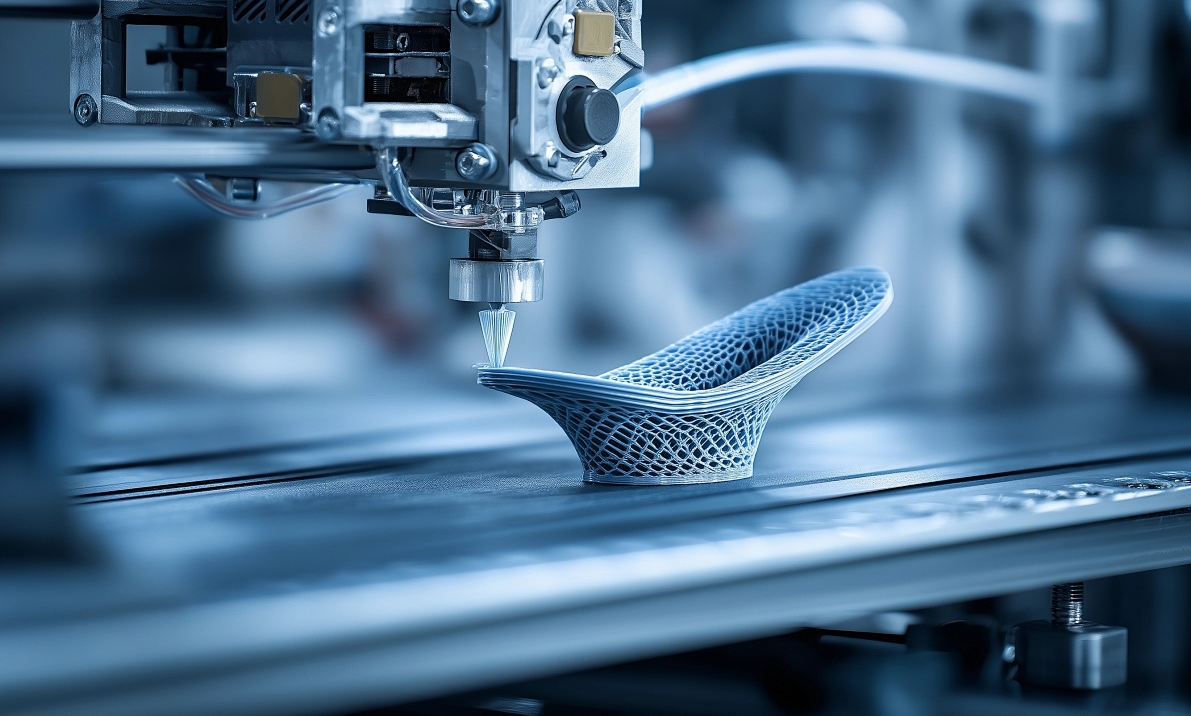

In the field of industrial manufacturing, resin 3D printing demonstrates unique value across multiple scenarios. For instance, R&D teams in electronics often use it to rapidly produce structural prototypes, verifying housing assembly, tolerance fits, and the design of small snap-fits. In automotive engineering, it is suitable for manufacturing prototypes with complex curves and rich details—such as lamp structures, internal flow guides, and functional brackets—effectively compressing development cycles. In automation equipment, resin printing can also flexibly produce various non-standard fixtures for positioning, inspection, or temporary clamping, helping engineers complete testing and tooling iteration more efficiently.

Based on our experience serving numerous industrial clients, the value of resin 3D printing lies not only in the technology itself but also in the ability to deliver parts that stably and efficiently meet engineering requirements. Utilizing industrial-grade SLA equipment and a mature database of process parameters, we ensure excellent detail reproduction and dimensional consistency for a wide range of prototypes, from precision electronic components to large automotive parts. Furthermore, we provide comprehensive post-processing support—including sanding and blasting for enhanced surface finish, painting to simulate final product color and texture, polishing of transparent resins for optical validation, and metallization to improve appearance and mechanical strength. Combined with our printing capabilities, these processes give your prototypes a finish that closely resembles mass-produced parts.

In summary, while resin printing excels in precision and surface quality, different 3D printing technologies each have their own strengths in material properties, mechanical performance, and cost. Depending on your specific application goals and budget, we can leverage our extensive material and process expertise to recommend the most suitable rapid prototyping solution for your needs. Please feel free to contact us for further consultation or a project quote.