Sheet metal fabrication holds a significant position in the manufacturing industry due to its unique advantages. It enables high-precision processing at low costs, offers high material utilization rates, and allows flexible production of products in various specifications through automated equipment. With strong adaptability, it is compatible with a wide range of metal sheets, effortlessly forming complex curves or intricate structures, making it a manufacturing process that combines efficiency and innovation.

In daily life and industrial production, sheet metal fabrication is ubiquitous. At home, the protective covers of air conditioner outdoor units and the casings of range hoods are all products of sheet metal fabrication, ensuring functionality while enhancing aesthetics. On city streets, the metal canopies of bus stops and the frames of outdoor billboards rely on sheet metal craftsmanship to withstand wind and sun exposure. In the industrial sector, server cabinets in data centers and battery enclosures for new energy vehicles are even more dependent on sheet metal fabrication, providing sturdy and reliable protective casings for various equipment.

Take household microwave ovens as an example—their casings are a typical product of sheet metal fabrication. By cutting, stamping, and bending stainless steel sheets, a precisely sized and compact casing is created, effectively shielding microwave radiation to ensure user safety while providing stable support for internal circuit components. Another example is the automatic ticket vending machines in urban rail transit. Their casings require high strength, impact resistance, and excellent heat dissipation. Sheet metal fabrication uses aluminum alloy sheets, processed through complex forming and welding techniques, giving the casing a refined appearance while meeting stringent usage requirements to ensure stable operation in high-traffic environments.

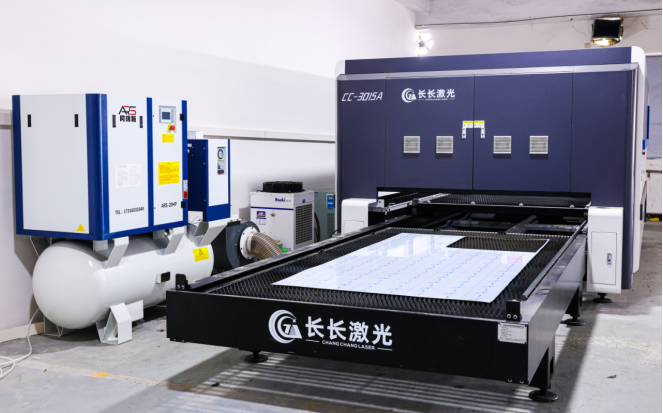

Our company has years of expertise in the sheet metal fabrication field, offering strong service advantages. With advanced equipment such as laser cutting machines and CNC bending machines, we ensure machining accuracy of up to ±0.05mm, meeting the production needs of various complex products. Our professional design team provides end-to-end services from blueprint design to sample production, quickly responding to customized demands. A mature supply chain system and strict quality control processes guarantee full control over product quality from raw material procurement to finished product delivery. Additionally, we offer efficient logistics services to ensure timely delivery. If you have any sheet metal fabrication needs, feel free to contact us anytime—we look forward to collaborating with you to create high-quality products!