CNC turning technology plays a pivotal role in modern manufacturing due to its high precision, efficiency, and broad material compatibility. Our turning solutions, with their exceptional performance and innovation, meet the complex part processing requirements across industries from aerospace to automotive, continuously advancing manufacturing toward greater efficiency and precision.

In contemporary manufacturing, CNC turning technology has become fundamental to metal processing with its unique advantages. It is not only suitable for precision machining of various metallic materials but also crucial for efficient production of complex components.

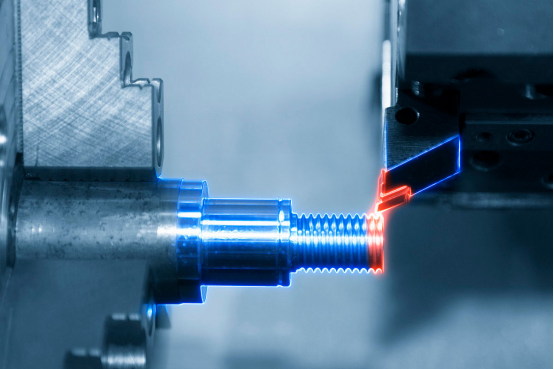

High Precision and Efficiency

One of the greatest advantages of turning technology is its ability to achieve high-precision machining. Through precise control of feed rate, spindle speed, and cutting depth, operators can meticulously adjust workpiece dimensions to meet strict engineering specifications. This high-precision capability makes turning indispensable in industries such as aerospace, automotive, and instrumentation. Additionally, turning typically employs continuous cutting methods, significantly boosting productivity—especially with multi-axis lathes, where multiple operations can be performed simultaneously, further enhancing machining efficiency.

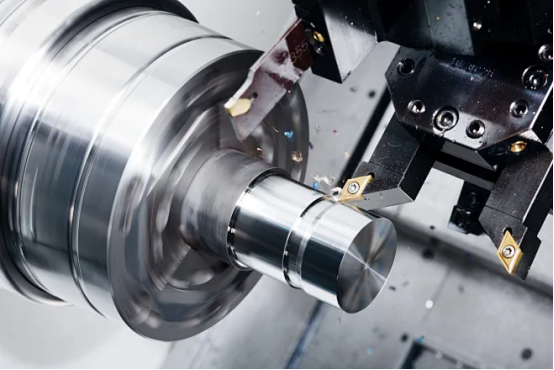

Extensive Material Compatibility

Another standout benefit of turning is its wide-ranging material adaptability. From common metals like steel, iron, copper, and aluminum to non-metallic materials such as plastics and ceramics, turning technology can effectively process them all. This material versatility not only expands the applications of turning but also establishes it as a vital component in multi-industry production. Moreover, by changing or adjusting tools and machining parameters, the turning process can handle workpieces with complex geometries, producing precision parts tailored to specific requirements.

High Cutting Forces and Machine Rigidity Requirements

A distinctive feature of turning is its universal material applicability. The technology can efficiently process everything from steel, iron, copper, and aluminum to non-metallic materials like plastics and ceramics. This adaptability not only broadens the scope of turning applications but also makes it an essential method in many production sectors. Furthermore, the turning process can accommodate workpieces with intricate shapes by modifying tools and machining parameters, ultimately creating precision components that meet specialized needs.

Yong'en Forming's turning solutions are highly regarded across various industries for their outstanding performance, reliability, and innovation. As technology continues to advance, Yong'en Forming will continue to explore new possibilities in the field of turning machining, providing customers with more efficient, precise, and cost-effective solutions.