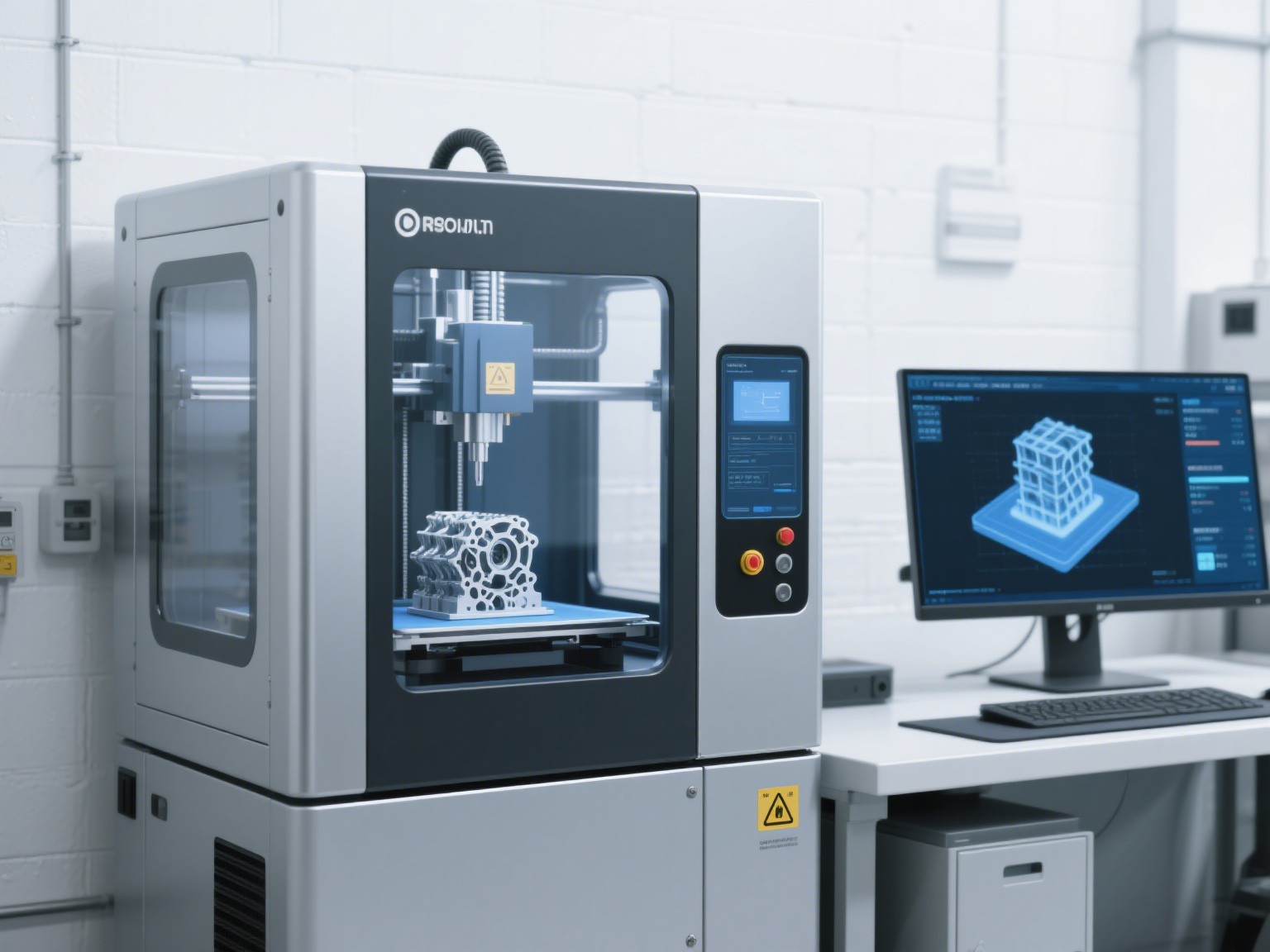

3D printing technology, as a rapid prototyping method, is transforming traditional manufacturing models with its unique charm. Based on digital model files, it uses powdered metals or plastics and other adhesive materials to construct objects through layer-by-layer printing. This technology breaks the limitations of traditional manufacturing in terms of shape complexity, enabling precise manufacturing of intricate structures. With short production cycles and strong customization capabilities, it has found extensive applications in various fields such as industrial manufacturing, healthcare, aerospace, and consumer products, bringing revolutionary changes to many industries.

In the consumer goods sector, 3D printing technology has spawned numerous creative products. Take personalized 3D printed headphones as an example. Traditional headphones often use standardized designs, making it difficult to fit perfectly into each individual's ear canal, resulting in discomfort and limited sound insulation. Personalized 3D printed headphones, on the other hand, scan the user's ear canal to obtain precise data and tailor the ear shell accordingly. This ensures a perfect fit, providing stability and comfort, while effectively enhancing sound insulation for a better auditory experience. Additionally, users can choose the color and pattern of the shell according to their preferences, creating a unique pair of headphones.

Furthermore, 3D printed architectural models serve as an essential tool for architects to showcase their design concepts. Traditional handmade architectural models are time-consuming and labor-intensive, and it's challenging to ensure precision for complex structures. In contrast, 3D printed architectural models can accurately reproduce every detail of a building based on the designer's digital model, including wall textures, window styles, and roof structures. This allows the architect's creativity to be perfectly presented and helps clients better understand the overall appearance and detailed design of the building.

If you are interested in 3D printing technology and want to customize your own 3D printed products, or if you need support in product development and production processes using 3D printing technology, please feel free to contact us. We have a professional technical team and advanced 3D printing equipment, capable of providing one-stop services from design modeling to printing production. Whether for small-batch personalized customization or large-scale production of complex structures, we can meet your needs. You can reach us by calling our service hotline at +86 18028781979, or by emailing yanse.ruan@aresmould.com. We are committed to serving you and helping bring your ideas and needs to fruition.