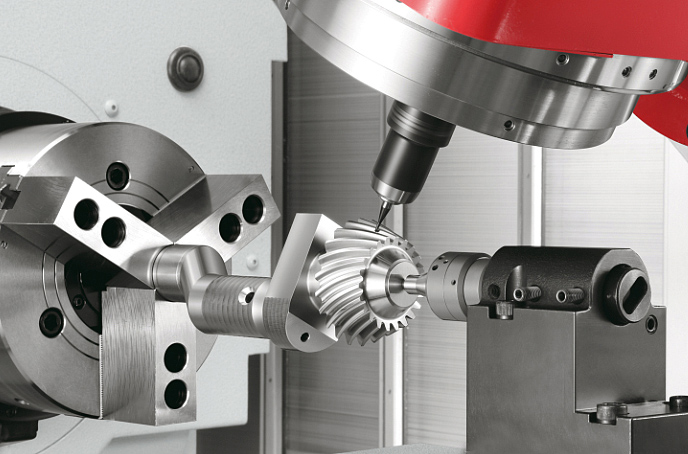

The engine block, as the core component of an automobile engine, features a highly complex structure and demands stringent machining precision. Traditional machining methods often require multiple setups, consuming a considerable amount of time, and setup errors can significantly affect the precision of the engine block. In contrast, five-axis CNC machining technology allows for the processing of multiple surfaces and complex hole systems in a single setup. With five-axis motion, the tool can flexibly adjust angles and precisely cut various parts. For example, in the machining of an engine block for a well-known automotive brand, the use of five-axis CNC machining resulted in a control of the cylinder inner diameter precision within ±0.01mm, and the piston stroke precision improved to ±0.02mm. This greatly enhanced the engine's power output stability and fuel economy. Additionally, the machining processes were reduced by 30%, and the production cycle was shortened by approximately 40%, effectively lowering manufacturing costs.

In the field of automotive mold manufacturing, five-axis CNC machining also offers significant advantages. As consumer demand for personalized automotive exteriors and interiors grows, the shapes of automotive molds are becoming increasingly complex. In the machining of automotive exterior component molds, five-axis CNC can achieve high-precision milling of complex curved surfaces. For instance, when machining a new type of car door cover mold, five-axis CNC, with its multi-axis motion capabilities, can accurately mill the mold surface with intricate curves and contours, achieving a surface roughness of Ra0.8μm or lower. This ensures that the produced door cover has a smooth appearance and high assembly precision. Moreover, five-axis CNC machining can also create fine textures and structures on the molds, meeting the unique design requirements for automotive interior components and providing strong support for innovation in automotive interiors.

If you are facing challenges in machining complex shapes or high-precision requirements in automotive parts processing or mold manufacturing, please feel free to contact us. We have a professional five-axis CNC machining team equipped with internationally leading processing equipment and rich experience in the automotive industry. Whether it's for engine components, automotive molds, or other complex automotive parts, we can provide customized solutions based on your specific needs. From design planning and manufacturing to quality inspection, we are committed to delivering exceptional quality and efficient service to help your automotive manufacturing projects succeed.