In the sheet metal fabrication industry, technological innovations have become the driving force breaking through traditional production barriers. From fundamental processing equipment to intelligent management systems, the deep integration of advanced technologies is making manufacturing more precise and efficient.

Laser cutting equipment is currently the "mainstay" of sheet metal processing. Equipped with fiber lasers and CNC systems, laser cutting machines can complete metal sheet cutting at speeds of several meters per second, delivering smooth, burr-free edges. Intelligent nesting software further optimizes cutting paths, increasing material utilization to over 90%. After adopting such equipment, an automotive parts manufacturer saw a threefold improvement in the efficiency of cutting complex components compared to traditional methods.

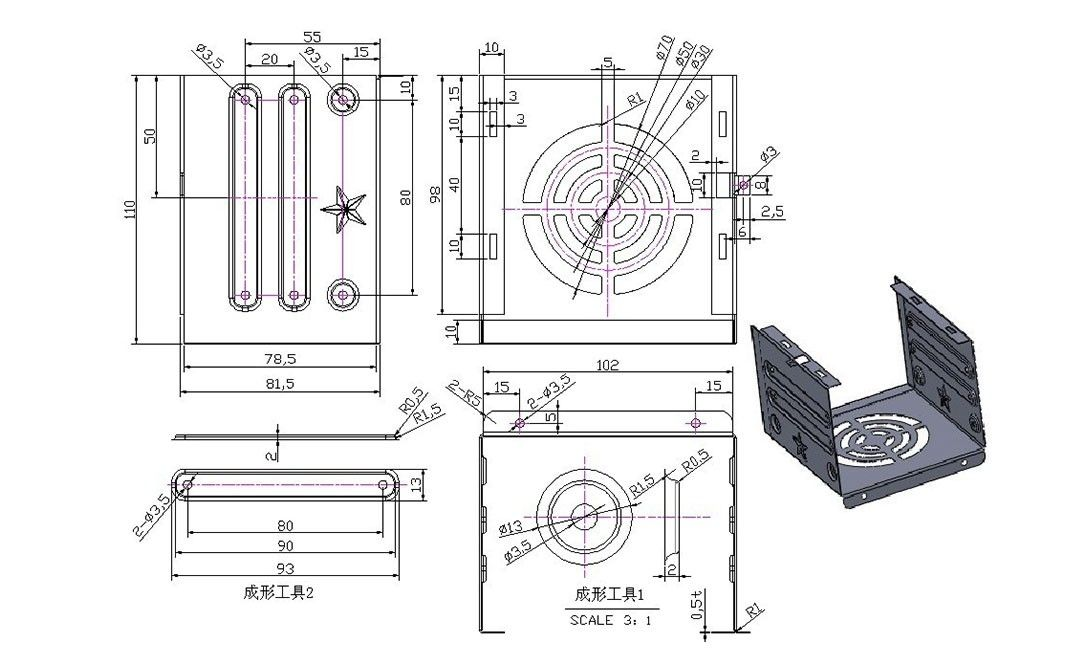

Intelligent press brakes also deliver outstanding performance. Fitted with servo motors and angle sensors, these machines can monitor pressure changes in real time during bending and automatically compensate for errors using built-in algorithms, ensuring that the angle deviation of each batch of products does not exceed 0.5 degrees. Coupled with 3D simulation software, they can also predict potential bending interference in advance, reducing trial runs.

Digital management terminals ensure full-process control. Operators can retrieve processing drawings and issue production instructions via industrial tablets, while real-time equipment data is uploaded to a cloud platform. Managers can monitor production progress and equipment status remotely via mobile devices, enabling efficient oversight.

These technological products are driving the transformation of sheet metal processing toward greater intelligence and precision. If you are looking to enhance your processing capabilities with advanced technology, feel free to contact us—let’s embark on a journey toward high-efficiency production together.