In the vast landscape of modern manufacturing, sheet metal parts have become the core components of countless products, from home appliances and automobiles to communication and medical equipment. It serves not only as the product's skeleton but also as a critical element for integrating design aesthetics and functionality. Today, YONG'EN FORMING would like to share our deep understanding and practical experience in sheet metal fabrication.

Sheet metal fabrication is not a single process, but a complex series of precision techniques. At YONG'EN FORMING, we integrate industry-leading equipment and processes to ensure every step meets the highest standards.

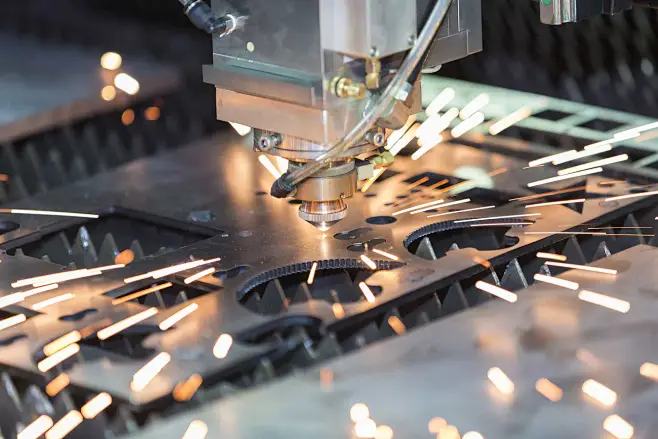

Blanking is the starting point of sheet metal fabrication, and its accuracy directly determines the quality of subsequent processes. We use advanced technologies such as high-power laser cutting and CNC punching to achieve precise cuts on various metal sheets, including stainless steel, carbon steel, and aluminum alloys. Laser cutting, in particular, with its high precision, narrow kerf, and clean edges, is ideal for complex shapes and high-requirement parts, laying a solid foundation for the final product.

Forming is the key to giving sheet metal parts their three-dimensional form. We use CNC press brakes with programmed controls to achieve precise bending angles and dimensions. This not only significantly improves production efficiency but also ensures consistency and accuracy, effectively eliminating potential errors from traditional manual operations. Whether it's a simple L-bend or a complex Z-shaped structure, we can achieve it perfectly.

Joining is a core process that ensures the integrity and strength of the product's structure. We are proficient in various welding techniques, including laser welding for thin sheets, high-efficiency and high-strength MIG/MAG welding, and spot welding for multi-point connections. These technologies allow us to select the most suitable joining method based on the specific needs of the part, ensuring a robust and reliable product structure.

A product's appearance and durability are equally crucial. Through meticulous surface treatments, we can provide an additional protective layer and aesthetic value to sheet metal parts. Our services include powder coating, plating, and oxidation, which not only offer effective corrosion and wear resistance but also allow for a variety of colors and textures to meet a client's design requirements.

As a full-service precision manufacturing provider, YONG'EN FORMING’s advantages extend far beyond a single sheet metal technology. We offer a holistic solution that covers the entire product lifecycle.

One-Stop Service: Our services encompass precision CNC machining (for both plastic and metal), sheet metal, 3D printing, and mold making. This means we can provide a seamless, all-in-one solution from prototype development to mass production, greatly simplifying our clients' supply chain management.

Rigorous Quality Standards: We understand that quality is the cornerstone of trust. As a long-term partner of renowned brands like Gree Air Conditioner, Skyworth, and others, our quality management system strictly adheres to the highest industry standards, ensuring every product we deliver meets a client's demanding specifications.

Rich Industry Experience: Our client base spans home appliances, automotive, high-tech, and more. Whether it's manufacturing an elegant casing for a home appliance (like the plastic CNC casing for Gree Air Conditioners) or providing complex internal brackets for a communication device, we have extensive successful experience.

Sheet metal fabrication is an art and science filled with both challenges and opportunities. At YONG'EN FORMING, we are not just fabricators; we are your strategic partners. We are dedicated to using advanced technology, a rigorous approach, and rich experience to turn your designs into high-quality physical products.

Feel free to contact us to explore the endless possibilities of precision manufacturing together.