In today's fast-changing market, product innovation is the core of a company's competitiveness. Rapid Prototyping is a key engine that accelerates this process, turning ideas into tangible products. It's more than just a technology; it's a new way of thinking that disrupts traditional product development models, making the journey from "zero to one" unprecedentedly efficient and controllable.

What is Rapid Prototyping?

Simply put, rapid prototyping is a collection of technologies that can quickly and affordably convert 3D digital models into physical objects. It overturns the traditional time-consuming and labor-intensive method of making prototypes. Using computer-aided design (CAD) and automated manufacturing, we can transform virtual models on a screen into tangible, testable objects in just a few days or even hours.

Rapid prototyping technologies are mainly divided into several categories:

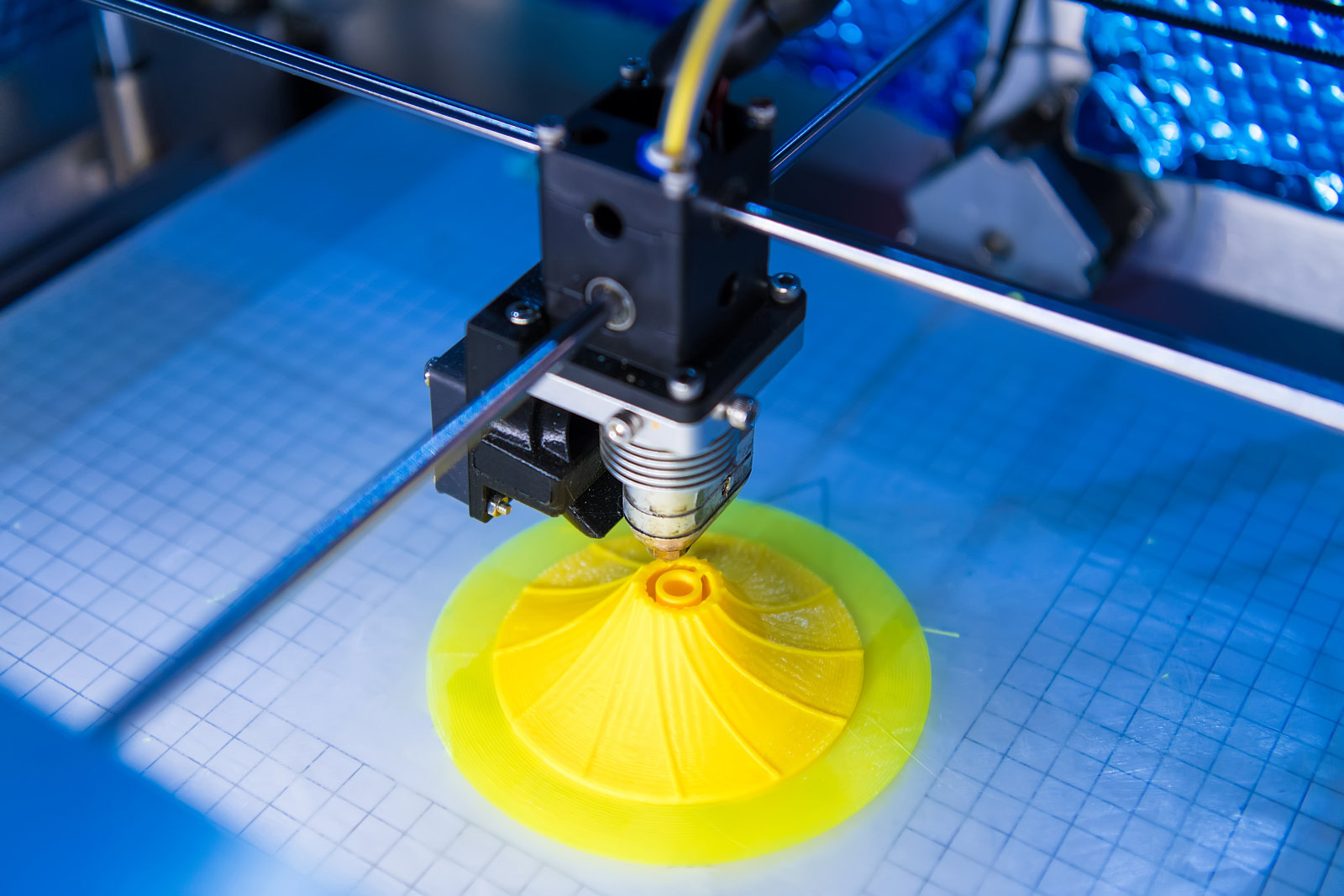

Additive Manufacturing (3D Printing): Builds objects by stacking material layer by layer, easily creating complex and non-standard geometries.

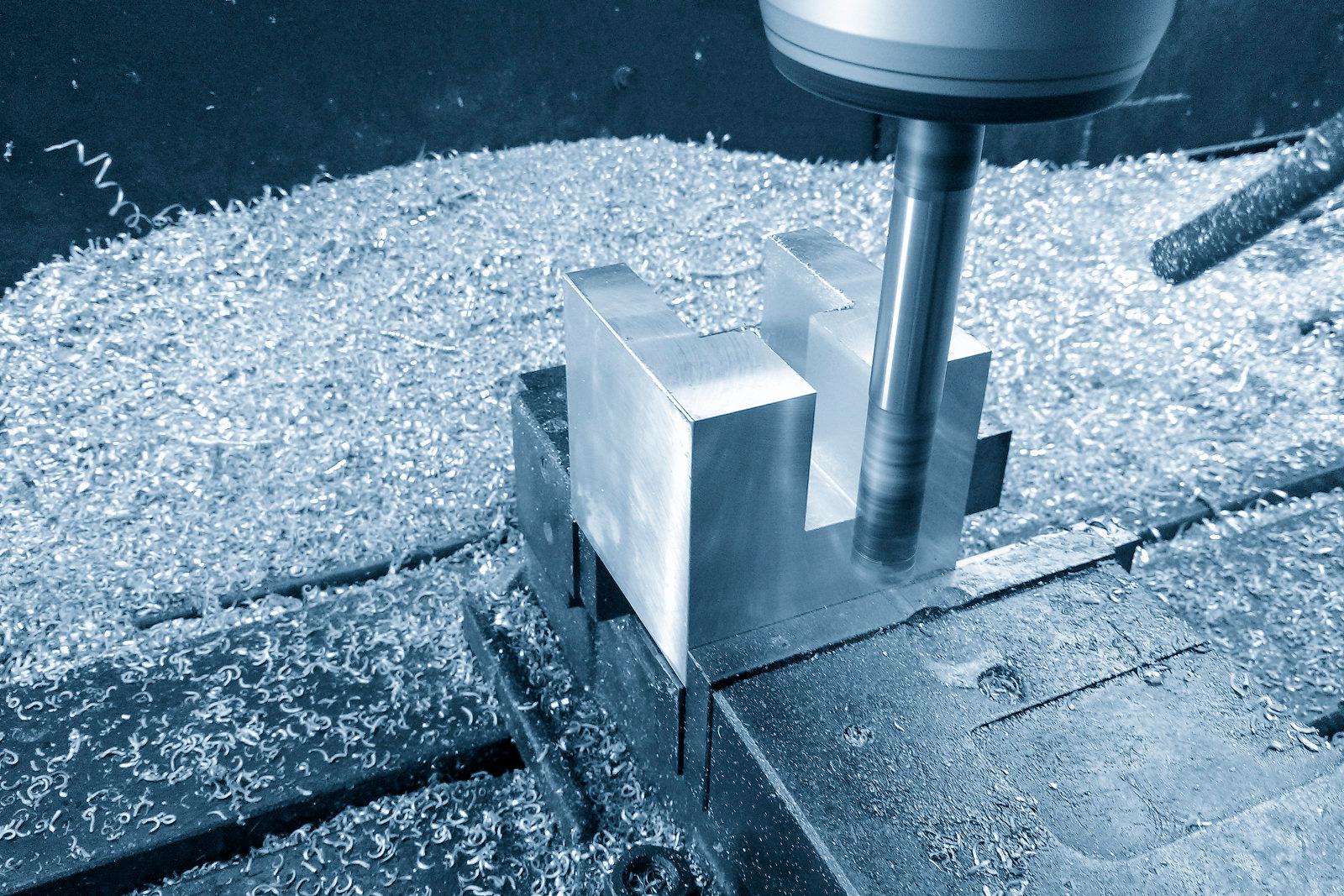

Subtractive Manufacturing (CNC Machining): Carves parts from a solid block of material with high-speed rotating tools, offering high precision and a wide range of material options.

Analogous Manufacturing (Vacuum Casting): Uses a silicone mold and resin materials to quickly replicate small batches of prototypes with low cost and a short cycle time.

The Core Advantages Rapid Prototyping Brings Us

By integrating rapid prototyping technology, we have experienced several core advantages firsthand:

1. Significantly Shortened Development Cycles, Gaining a Market Head Start

In the past, creating a high-fidelity prototype could take weeks. Now, we can complete multiple design iterations in less than a week. This incredible speed allows us to quickly validate new ideas and bring new products to market at a faster pace, giving us a competitive edge.

2. Reduced Development Risks and Costs

In traditional development, once an expensive mold is made, any design flaw leads to significant rework costs. With rapid prototyping, we can identify and correct design issues—such as structural interference, assembly errors, or poor user experience—early in the low-cost prototype phase. This fundamentally eliminates the risks of mass production and saves the company a great deal of time and money.

3. Optimized Communication and Collaboration

A tangible, touchable prototype is far more convincing than a two-dimensional drawing or a render on a screen. It provides a "universal language" for our design, engineering, sales, and management teams. When everyone can hold and discuss the physical prototype, communication efficiency is greatly enhanced, and decision-making becomes more accurate and faster.

Conclusion

Rapid prototyping is more than just a tool; it has become integrated into our culture of innovation and our workflow. It gives us the courage to experiment, the momentum to accelerate, and the assurance of success. We firmly believe that by continuously embracing and applying such advanced technology, we can better serve our customers, create more exceptional products, and continue to lead innovation in our industry.