In the sheet metal fabrication industry, we know that while advanced equipment is important, what truly defines product quality and efficiency are the seemingly insignificant details. Through years of practice, we've compiled some valuable insights that we hope to share with our peers to grow together.

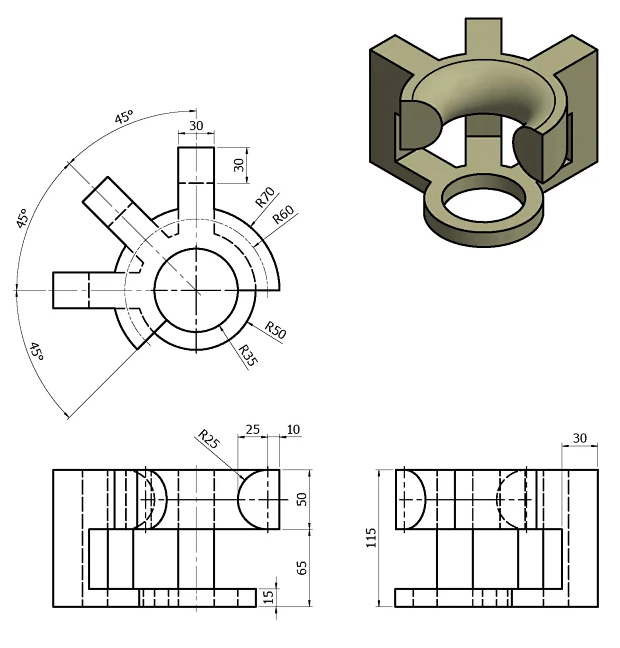

When we receive a new blueprint, we never rush to start work. First, we spend time carefully studying every dimension, tolerance, and special requirement. Even a millimeter's deviation can lead to the entire batch being scrapped. Effective communication with the customer to clarify any questions is the first step to ensuring a smooth project.

The flat pattern of a sheet metal part is crucial for material utilization and the difficulty of subsequent processing. We use professional software to simulate and consider factors like the bend deduction and hole locations. A well-designed flat pattern can maximize material savings, reduce waste, and simplify later bending and welding.

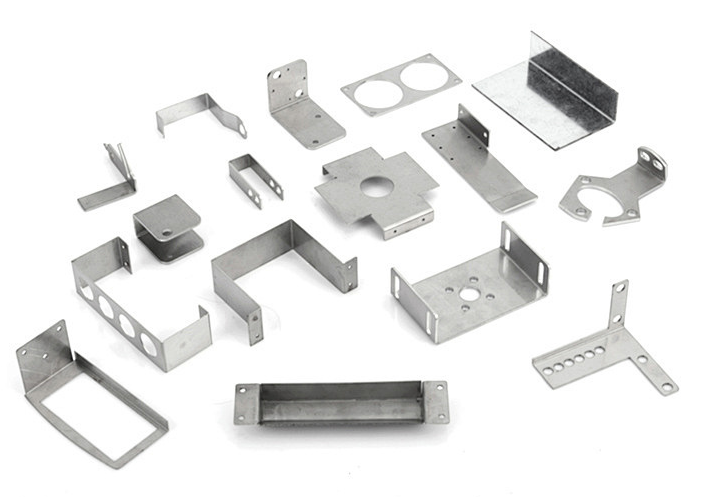

Choosing the Cutting Process: For complex, irregular shapes and thin sheets, we prefer laser cutting because of its high precision and smooth edges. For large batches of parts with regular holes, a CNC punch press is more efficient and cost-effective.

Planning the Bending Sequence: When performing CNC bending, we must carefully plan the bending sequence to avoid interference. Following the principle of "from small to large, from inside to outside" can effectively increase efficiency and ensure accuracy.

Welding is a critical step in joining sheet metal parts. We adhere to the "less is more" principle, using the smallest possible weld to ensure strength. This not only reduces thermal deformation but also saves a significant amount of time during later polishing. For polishing, patience and meticulousness are key; only a smooth surface can lay a solid foundation for the final surface treatment.

Quality control is not just a final check; it is the lifeline that runs through the entire fabrication process. From material inspection upon arrival, first-piece inspection, and in-process spot checks, to the final dimension verification of the finished product, every step must be strictly followed. We encourage our employees to develop the habit of "self-checking," making everyone a gatekeeper of quality.

In conclusion, sheet metal fabrication is a highly practical skill. It requires us to continuously learn new knowledge and use new equipment, but most importantly, to approach every detail with a rigorous attitude and a spirit of excellence. Only then can we stand out in a competitive market and provide truly outstanding products to our customers.