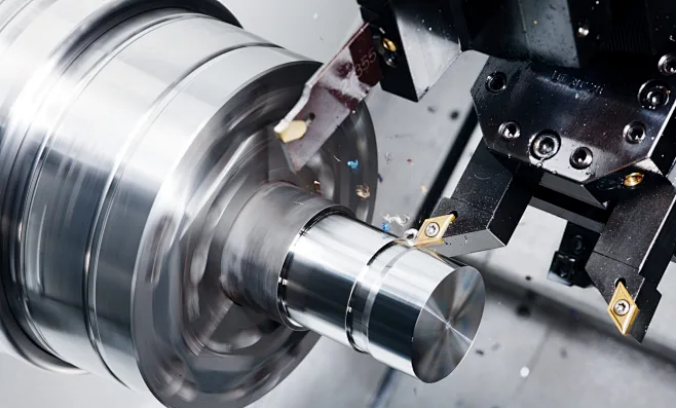

As a core technology in modern manufacturing, CNC (Computer Numerical Control) machining uses computer programs to precisely control machine tools, transforming raw materials such as metals and plastics into high-precision, high-quality components through processes like turning, milling, and drilling. With advantages such as high automation, consistent accuracy, and strong repeatability, CNC machining is widely applied across industries. Particularly amid the rapid growth of the smart home sector, CNC machining is quietly transforming lifestyles by equipping smart devices with superior reliability and refined aesthetics.

The applications of CNC machining are ubiquitous in daily life. Take smartphone cases, for example—many premium aluminum alloy phone shells are products of CNC machining. A flagship smartphone model might feature a case measuring approximately 160mm in length, 78mm in width, and just 7.5mm in thickness. Through CNC machining, a solid aluminum block undergoes milling, drilling, and polishing to precisely form the shell’s contours, button recesses, and camera cutouts. Thanks to CNC’s high precision, dimensional tolerances are kept within ±0.05mm, with surface roughness as fine as Ra0.4μm. This ensures a sleek, lightweight design while maintaining structural strength and premium tactile quality, delivering an exceptional user experience.

Another example is the stainless steel kitchen faucet, whose intricate internal waterways and elegant exterior rely heavily on CNC machining. A typical single-hole faucet, with a main body diameter of about 30mm and height of 120mm, is crafted by first turning a stainless steel rod into its basic shape, then milling precise internal channels to ensure smooth water flow. CNC machining also enables delicate decorative engravings on the faucet’s surface, which is then polished to combine functionality with visual appeal. The entire process guarantees both leak-proof durability and aesthetic refinement.

Our company specializes in CNC machining services, with extensive experience in producing smart home components. Equipped with advanced machinery—including 5-axis machining centers and high-speed CNC lathes—we work with materials like aluminum alloy, stainless steel, and engineering plastics, accommodating parts as large as 3000mm × 1500mm × 1000mm.

Our expert team, comprising seasoned engineers and master programmers, optimizes manufacturing processes based on clients’ design blueprints and functional requirements. We offer end-to-end solutions, from structural design and prototyping to mass production. Rigorous quality control measures are enforced at every stage, from raw material inspection to final product testing, ensuring unwavering reliability.

Additionally, we provide rapid prototyping services, delivering samples within 72 hours to accelerate product launches. If you have CNC machining needs, feel free to contact us—we look forward to collaborating to create smarter, more comfortable, and higher-quality living experiences for homes everywhere!