Turn-mill compound machining represents state-of-the-art manufacturing technology that integrates multiple processes including turning, milling, boring and drilling. By enabling multi-axis synchronization and complete machining in a single setup, it dramatically reduces errors from repeated fixturing, achieving micron-level precision with surface roughness under Ra0.8μm. Equipped with intelligent CNC systems and in-process inspection devices, our systems dynamically optimize tool paths and cutting parameters in real-time. This advanced technology excels not only with challenging metals like titanium alloys and stainless steel, but also handles engineering plastics and composites with exceptional capability. Compared to conventional methods, it delivers over 50% productivity improvement, providing reliable, high-efficiency solutions for precision component manufacturing.

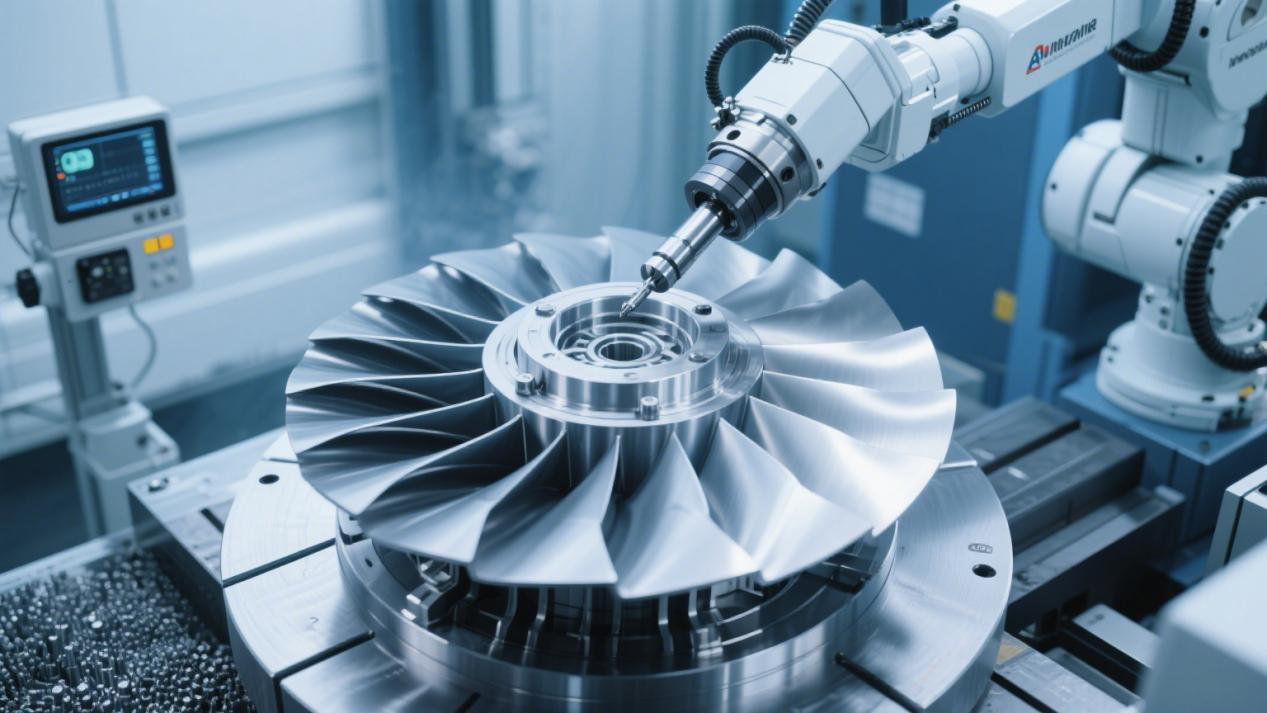

Case Study 1: Aircraft Engine Impeller

The impeller (Ø350mm × 180mm) with 24 twisted blades and complex hub geometry was machined from Inconel 718 - a notoriously difficult nickel-based superalloy. Our turn-mill process began with OD/face turning for rough stock removal, followed by 5-axis contour milling using Ø8mm ball end mills at 0.1mm stepovers. Real-time tool orientation control maintained blade profile accuracy within ±0.015mm. For the 12× Ø6mm × 30mm deep mounting holes, combined drilling/milling achieved positional accuracy of ±0.02mm. Final results: Ra0.6μm surface finish with 58% cycle time reduction (12hrs→5hrs) while maintaining critical balance tolerances.

Case Study 2: Medical Instrument Shaft

This surgical component (Ø12mm × 200mm) required precision helical flutes (3mm×2mm), reference flats, and Ø1.5mm vent holes in medical-grade 316L stainless. Our turn-mill approach delivered:

Cylindricity: ±0.003mm

Helix pitch accuracy: ±0.01mm

Vent hole tolerance: ±0.005mm

Flatness: ±0.002mm

Post-process electropolishing achieved Ra0.2μm finish, exceeding medical cleanliness standards while improving productivity by 60%.

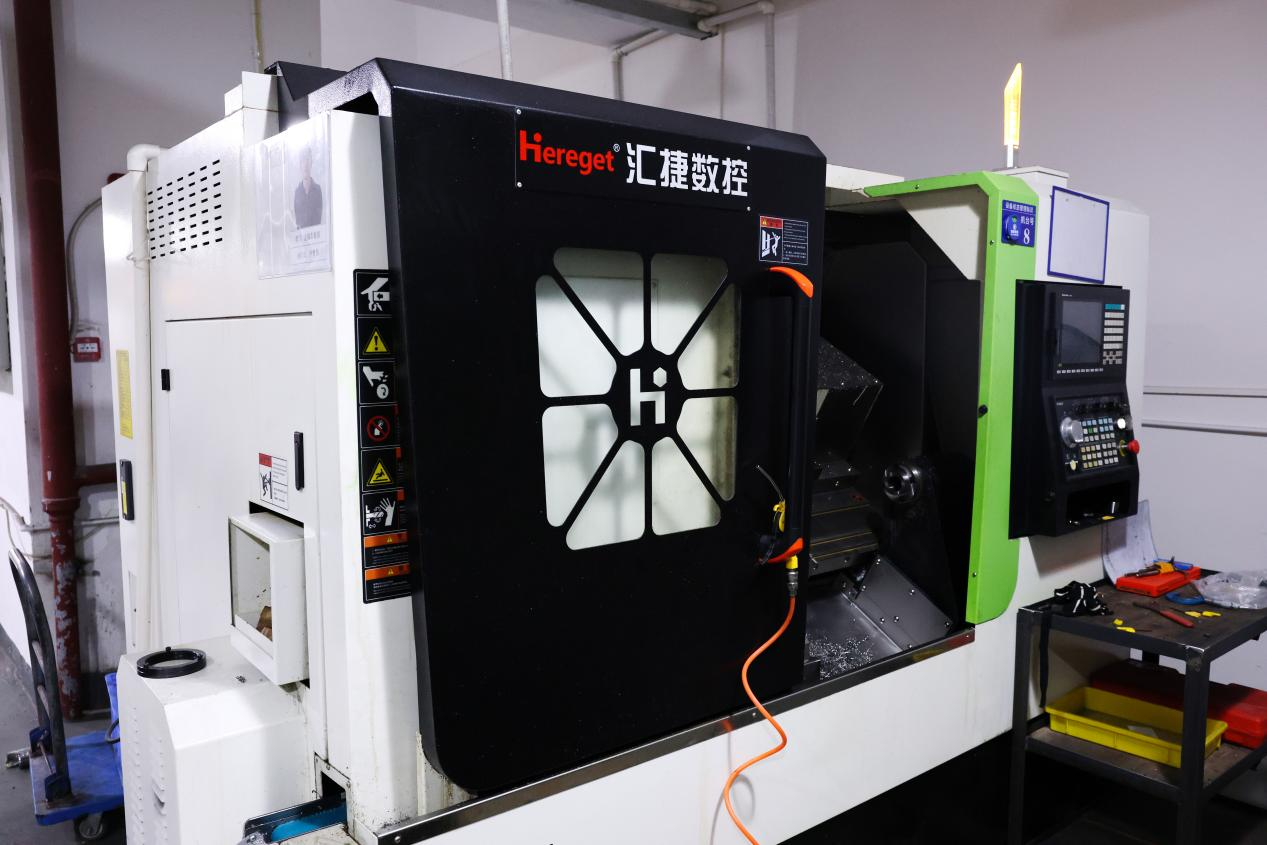

Why Choose Our Turn-Mill Services?

Partner with us for manufacturing excellence featuring:

✓ World-class multi-axis turn-mill centers

✓ Senior engineer-led technical teams

✓ Full-service solutions from DFM to delivery

✓ ISO 9001-certified quality systems

✓ 48-hour rapid prototyping response

✓ 99% on-time delivery guarantee

Contact us today for your customized precision machining solution!